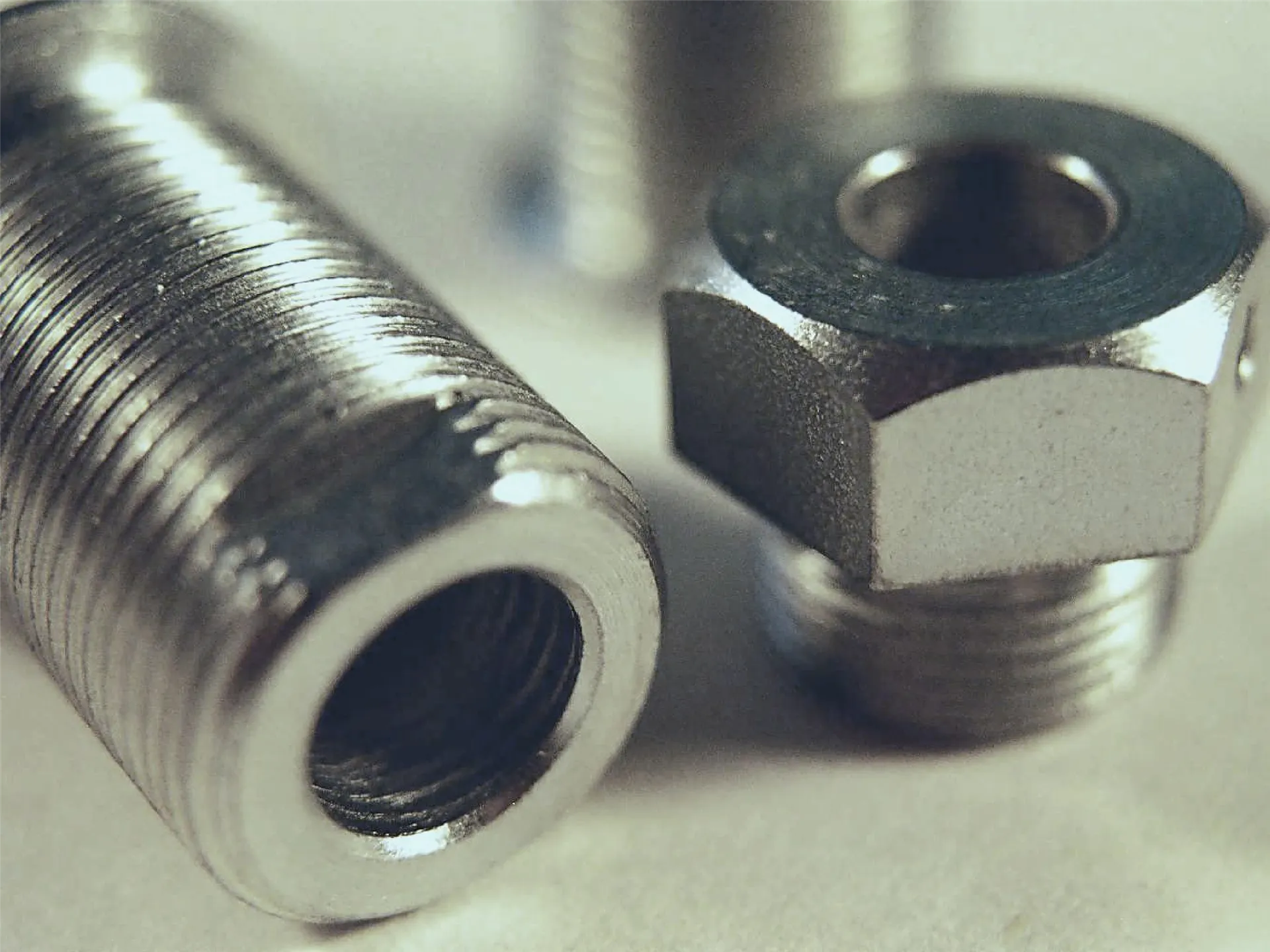

ZINC PLATING

<

>

>

ZINC PLATING

- What properties should the part have after coating?

- Is corrosion protection a priority? Is a decorative finish required?

- Or are only functional properties a priority?

- Or should it be a combination of these requirements?

The process selection is entirely determined according to our customers' needs!

With a very wide and effective product range, Anka Galvano Kimya is capable of meeting all the needs of the traditional electroplating industry.

- ZINKOR ET - alkaline zinc process

Provides excellent brightness across all current areas on the part.

Very good and adjustable metal distribution.

High plating speed.

Excellent throwing power. - VÍSZINC LC - alkaline zinc process

Process suitable for post-coating forming.

Excellent adhesion.

Successful process for long parts in alkaline zinc plating. - ZINKOR KL-20 - matte alkaline zinc process

Adjustable for satin-matte appearance.

Very good metal distribution.

High plating speeds. - LUNACID - acidic zinc process

Contains no chlorinated aromatic brighteners (AOX).

High clouding temperatures due to use of state-of-the-art wetting agents.

Excellent brightness.

Low consumption.

Excellent brightness and throwing power.